Our Services

Reliable Sewer Solutions for Commercial, Municipal & Industrial Projects Across Michigan

Pipe Cleaning & Maintenance

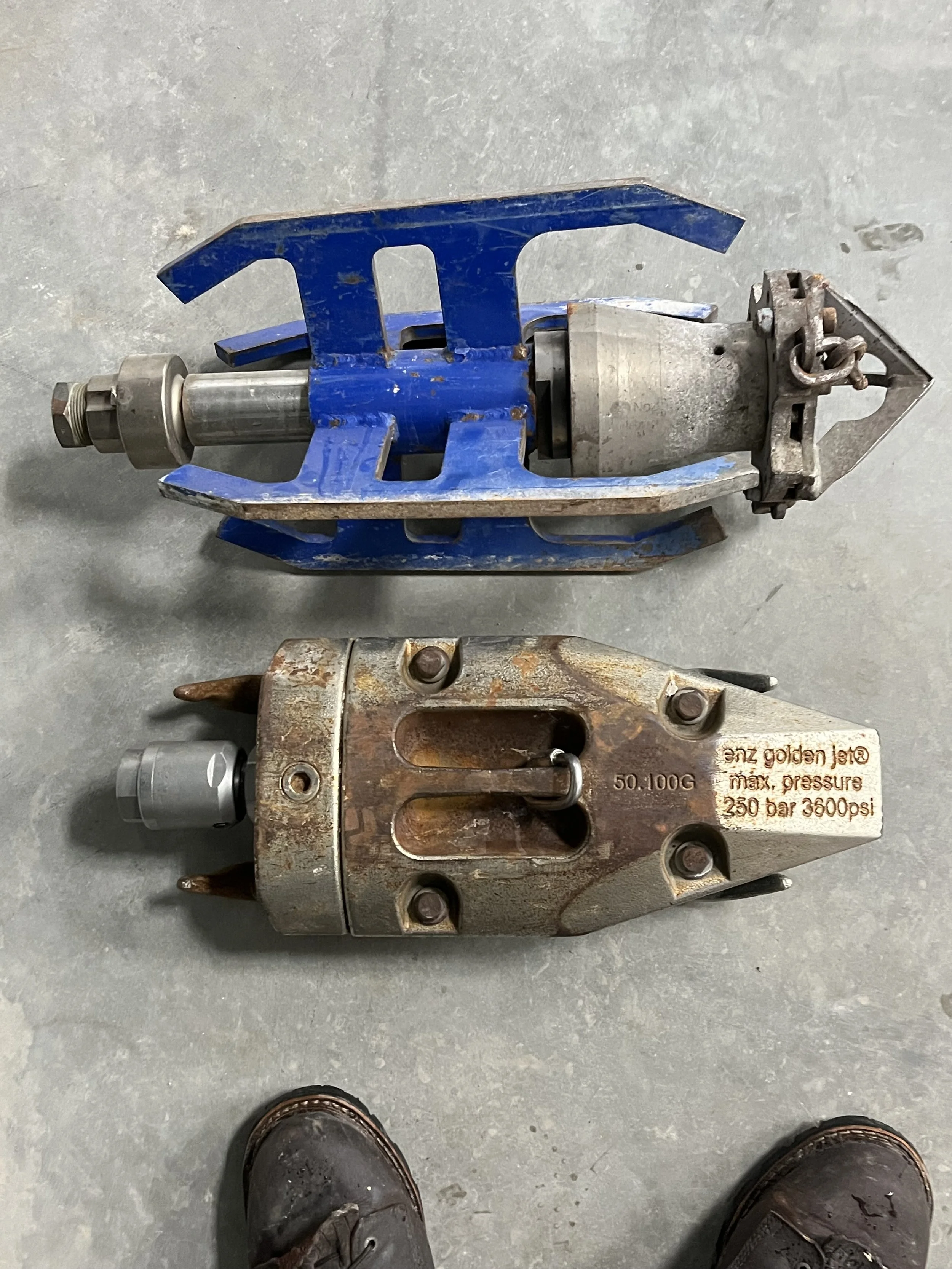

High-pressure jetting removes roots, grease, and debris to restore flow and prevent backups.

What We Do: We clean sanitary and storm sewers using high-pressure jetting to remove blockages and buildup.

How it Works: Specialized nozzles and water jets clean pipe interiors safely and efficiently.

Best For: Municipal maintenance, storm systems, grease removal.

Benefits

Restores optimal flow by removing grease, scale, roots, and other blockages

Improves the performance and longevity of both sanitary and storm sewer systems

Minimizes the risk of backups and costly repairs

Handles tough jobs with precision using advanced jetting equipment and nozzles

Includes specialized services like:

Root, debris, and calcium removal

Catch basin cleaning and maintenance

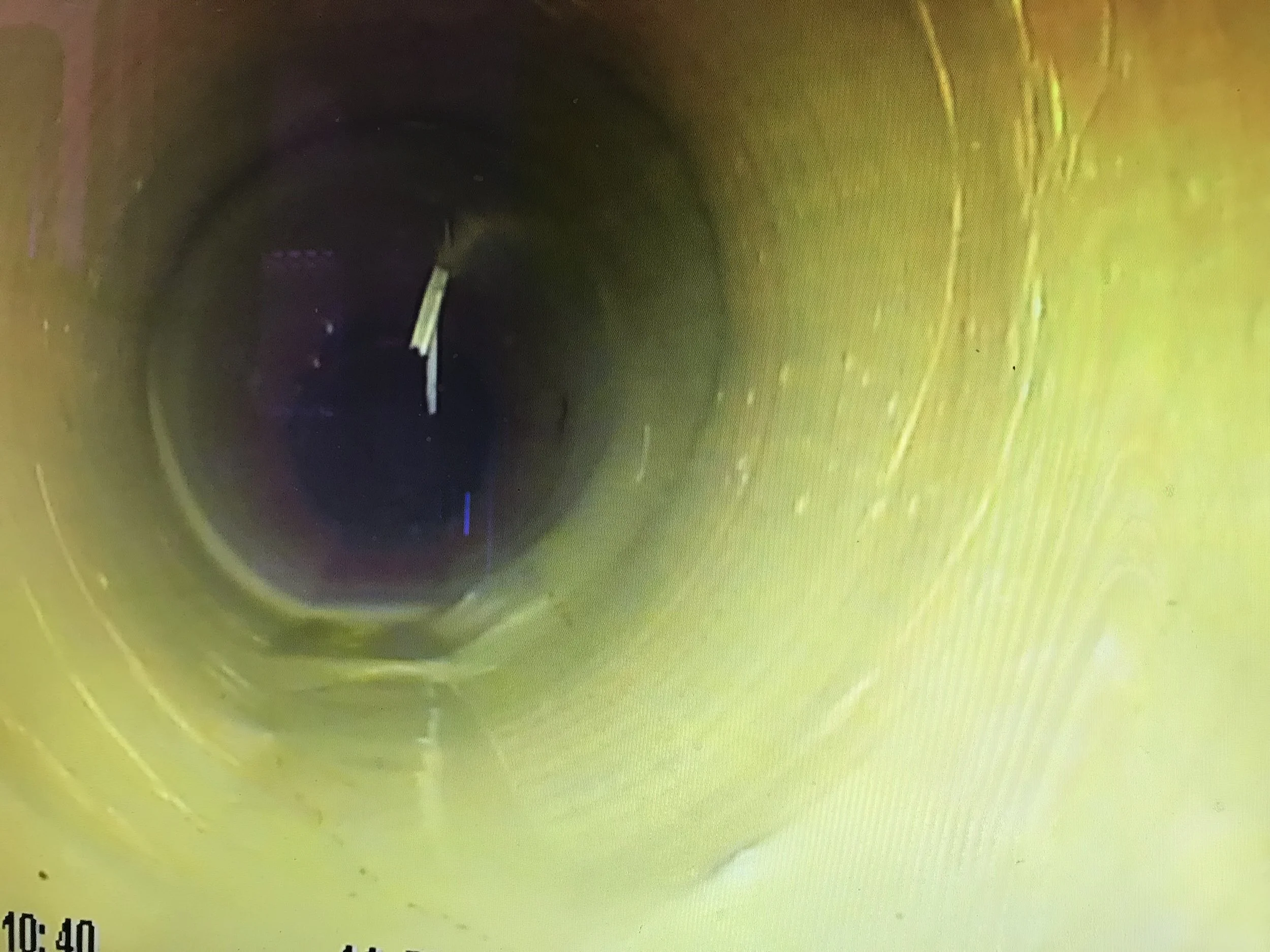

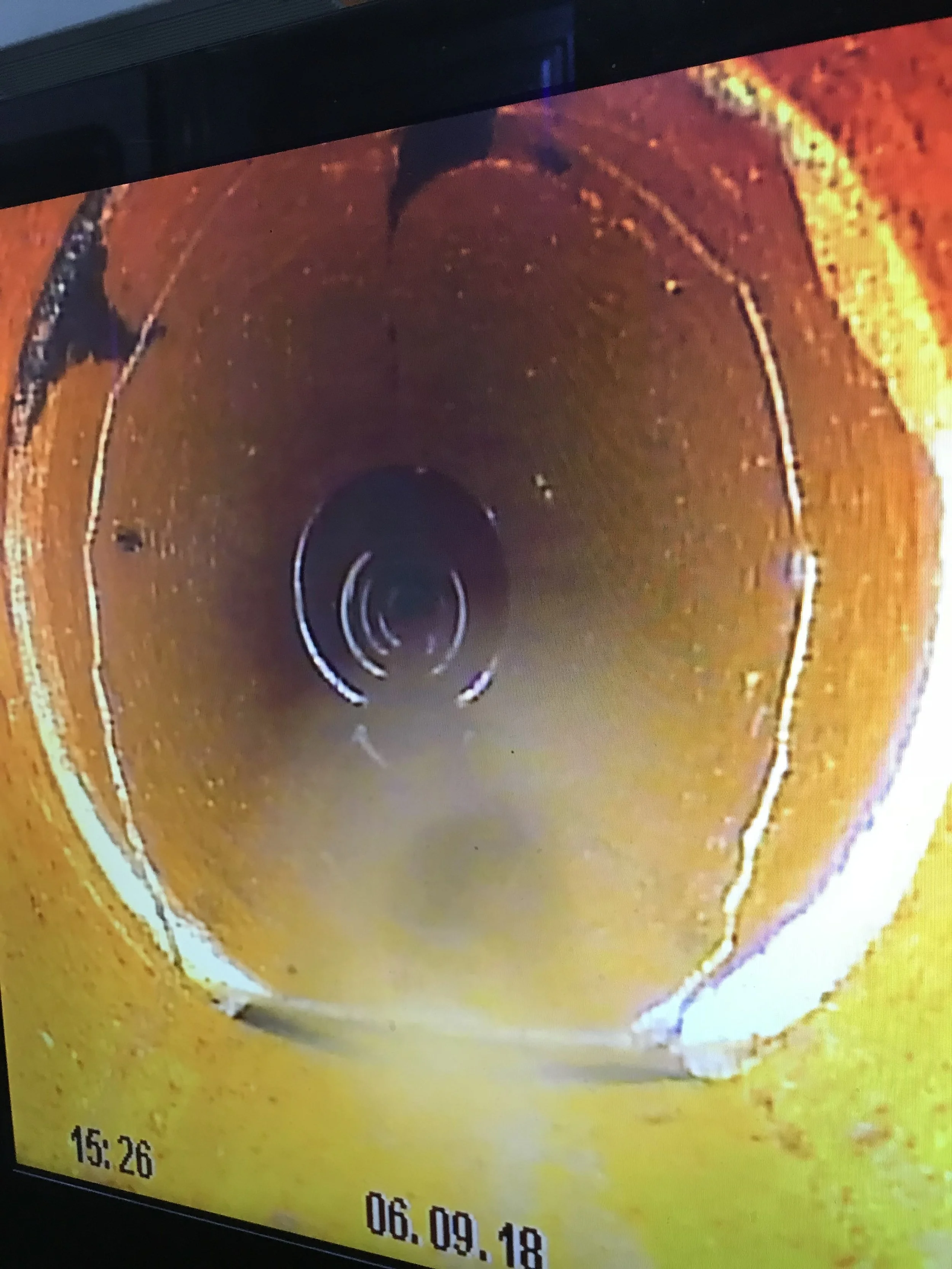

CCTV Sewer

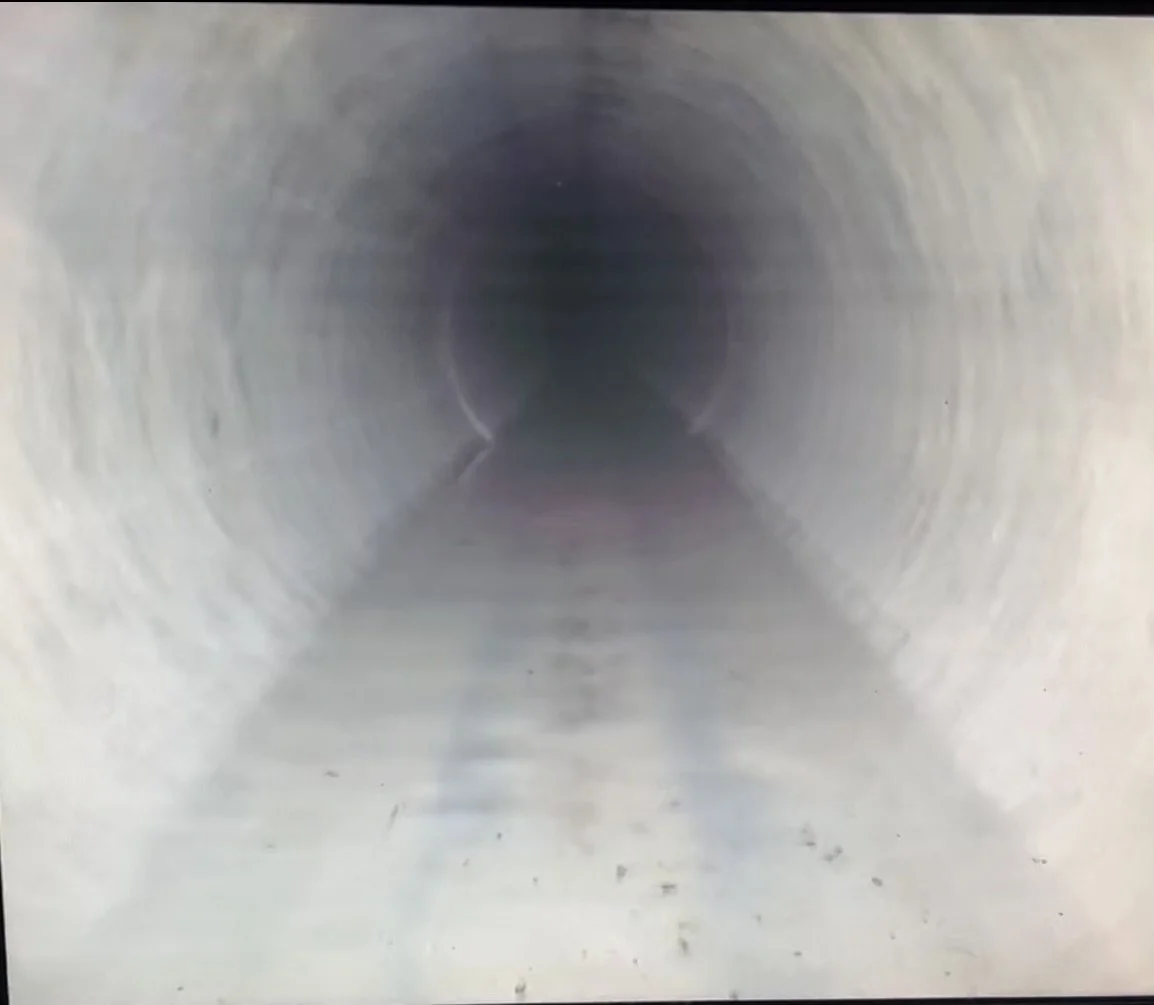

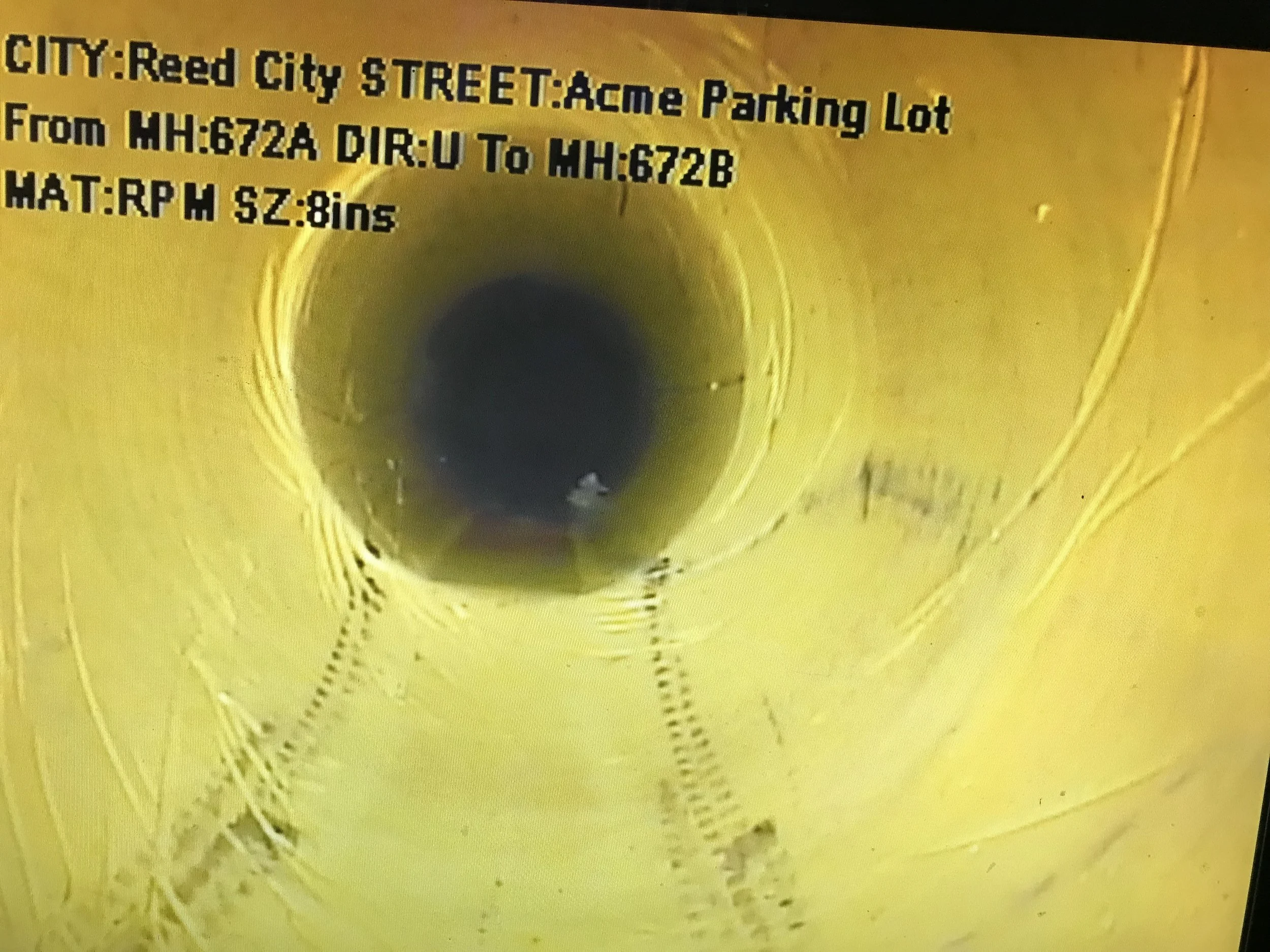

High-definition cameras provide real-time visuals to diagnose issues without digging.

What We Do: We inspect sewer lines using PACP-certified CCTV technology to assess conditions and locate issues.

How it Works: Our operators guide high-res cameras through sewer lines and record detailed internal views.

Best For: Pipe condition assessment, pre/post rehab inspections, troubleshooting.

Benefits

Provides high-definition, real-time visuals of sewer conditions

Identifies blockages, cracks, corrosion, and root intrusions without excavation

Enables accurate diagnostics in both mainlines and lateral pipes

Supports proactive maintenance and targeted repairs

Helps extend the lifespan of your sewer system

Cost-effective, non-invasive solution that reduces guesswork and unnecessary digging

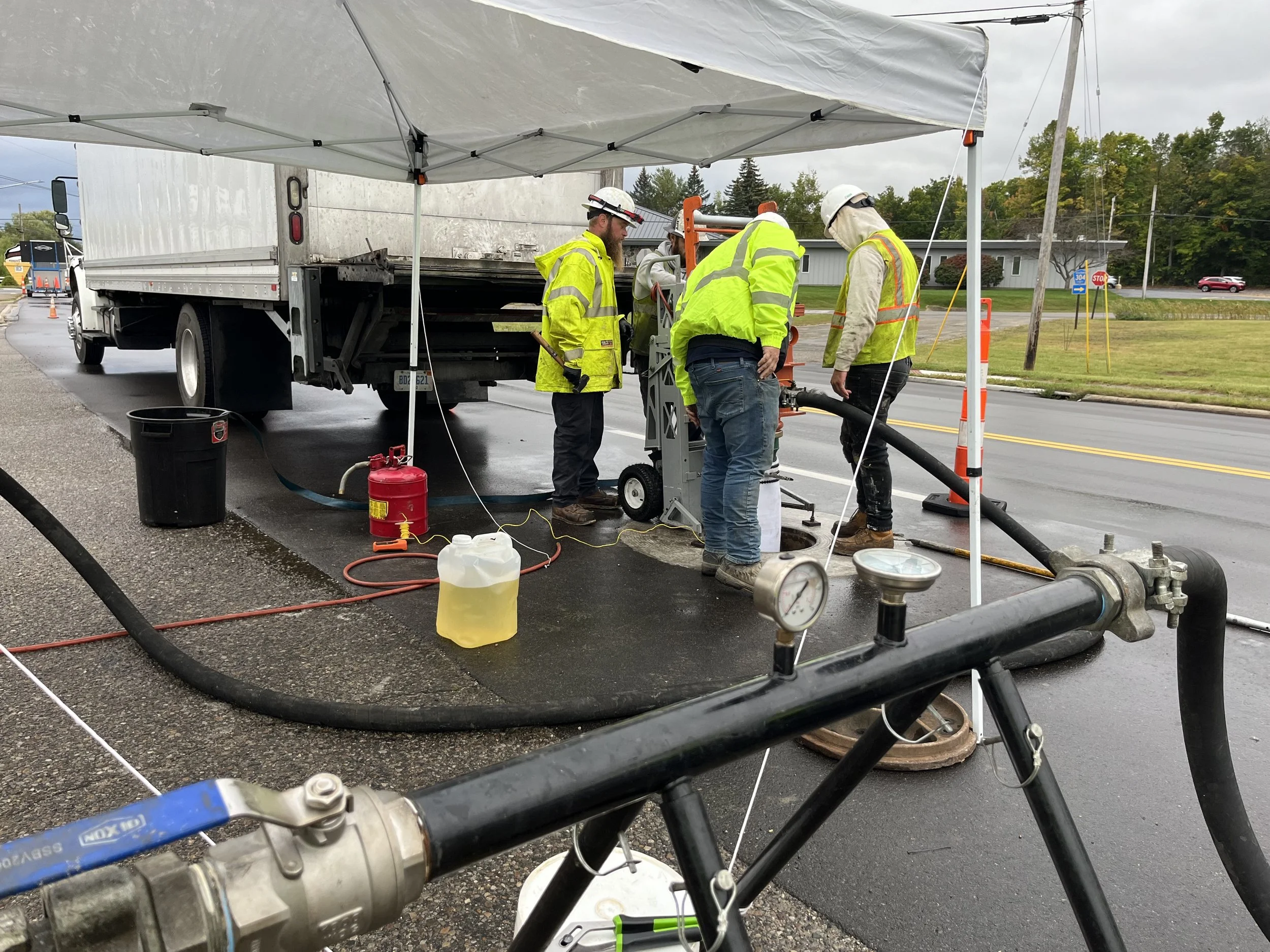

Hydro Excavation

A safe, precise method for exposing underground utilities using pressurized water and vacuum.

What We Do: We use hydro excavation to dig without damaging underground infrastructure.

How it Works: High-pressure water loosens soil, while vacuum systems remove debris cleanly.

Best For: Utility locating, confined spaces, potholing, daylighting.

Benefits

Reduces the risk of damaging underground utilities during excavation

Provides precise, controlled digging ideal for utility locating and sensitive areas

Minimizes surface disruption and cleanup compared to traditional methods

Requires less manpower and delivers faster, cleaner results

Ideal for exposing sewer lines, pipes, and infrastructure safely

Supports compliance and safety in municipal, industrial, and commercial applications

CIPP Lining

(Cured-In-Place Pipe)

Trenchless pipe rehab method that reinforces and renews existing sewer lines.

What We Do: We install resin-saturated liners into damaged pipes and cure them in place to create a new pipe within.

How it Works: Liners are inserted and cured with steam or UV light to harden into a durable new pipe.

Best For: Urban areas, deteriorating pipes, situations where digging is disruptive.

Benefits

Restores pipes without the need for excavation—minimal surface disruption

Cost-effective alternative to full pipe replacement

Quick installation process reduces system downtime

Durable, corrosion-resistant liner extends pipe lifespan

Improves flow efficiency with a smooth, seamless interior

Environmentally friendly by minimizing soil disturbance and surface damage

Ideal for urban areas and busy infrastructure where trenching isn’t feasible

Spin Casting

360° application of a new lining inside large-diameter pipes and vertical structures.

What We Do: We apply structural coatings to manholes and pipes using spin-cast technology.

How it Works: A rotating applicator distributes the lining material evenly inside the structure.

Best For: Manholes, culverts, large sewer mains, and corroded structures.

Benefits

Applies an even, 360° coating for consistent structural reinforcement

Strengthens degraded pipes, manholes, and catch basins without full replacement

Resistant to corrosion, chemical exposure, and abrasion

Restores flow efficiency with a smooth, obstruction-free interior

Minimally disruptive—requires little to no excavation, ideal for urban environments

Extends the lifespan of aging infrastructure and improves long-term system performance

Sectional Lining

(Point Repair)

Localized repairs for damaged pipe sections without full replacement or excavation.

What We Do: We use flow-through packers and liners to repair small pipe sections.

How it Works: Resin-impregnated patches are positioned inside pipes and cured to seal damage.

Best For: Isolated cracks, holes, and intrusions in 6"+ pipes.

Benefits

Quickly repairs localized damage such as cracks, holes, or leaks without full pipe replacement

Minimally invasive—no need for excavation or bypass in most cases

Preserves surrounding infrastructure and reduces project disruption

Flow-through packers allow continued system use during repair

Creates a seamless, reinforced connection between mainlines and lateral pipes

Cost-effective solution that extends the life of aging or compromised pipe sections

Specialty Robotic Cutting

Advanced remote-controlled machines perform grinding, reinstatement, and precision cutting tasks.

What We Do: We use robotic cutters to remove blockages, reinstate laterals, and prep pipes for lining.

How it Works: Remote-operated systems navigate pipes and perform precision tasks inside the sewer line.

Best For: Lateral reinstatement, pipe prep, roots or obstructions removal.

Benefits

Performs precision cutting, grinding, and reinstatement with minimal disruption

Ideal for accessing hard-to-reach or damaged pipe sections

Enables accurate lateral reinstatement following pipe lining

Supports detailed prep work for CIPP, sectional lining, and other rehab methods

Reduces the need for excavation or manual entry into confined spaces

Remote-controlled technology ensures safer, faster, and more efficient repairs

Have Questions or Need a Quote?

Whether you're planning routine maintenance or a major rehab, our team is ready to help.